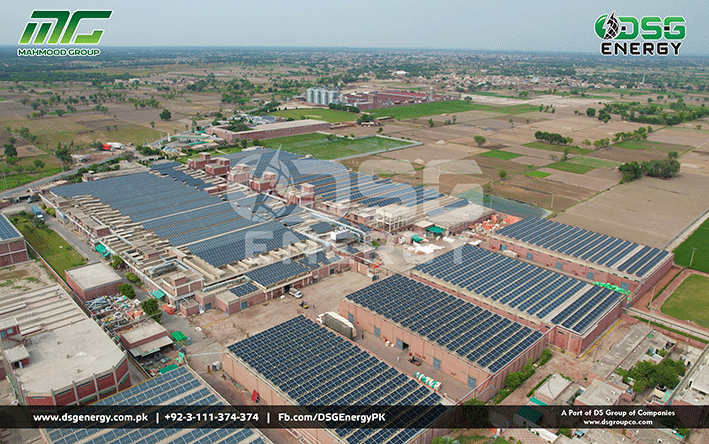

Masood Spinning Mills | 7 MW Grid Tied Solar Power Plant Case Study

The textile industry is a vital sector in global economic growth, providing employment and driving prosperity. However, traditional textile manufacturing processes often rely on traditional energy sources that contribute to environmental degradation and global warming. Additionally, the reliance on non-renewable energy sources such as fossil fuels further exacerbates the environmental impact, as the combustion of these fuels releases carbon dioxide (CO2) and other harmful pollutants into the atmosphere.

Masood Spinning Mills, situated in Kabirwala, recognized the urgent need to address its environmental impact and sought sustainable energy solutions to mitigate the harmful effects of its operations. To giving back to Motherland, Masood Spinning Mills chose DSG Energy, a leading solar company, to install a 7MW solar power plant. The solar installation aimed to harness the abundant renewable energy resource, the sun, and convert it into clean electricity. DSG Energy implemented a comprehensive plan to maximize the effectiveness and efficiency of the solar power plant, utilizing a combination of 4MW ground-mounted and 3MW rooftop.

The installation utilized a mix of solar panel types, including poly, mono, and bi-facial panels, to maximize energy generation. ABB and Huawei inverters were chosen for efficient energy conversion. Despite the buildings’ age, the stable roofs provided a solid foundation for the panels. P2 and P3 structures were implemented on Unit 1, featuring 390W panels. However, labor issues, similar to those encountered at the Masood site, required effective management strategies. In addition to the Kabirwala installation, another site with 5MW capacity was established, with 1MW on the rooftop and 4MW on the ground. The ground-mounted section underwent land compression to enhance its strength, a process that took approximately 45 days. The 4MW installation was divided into two 2MW sections, incorporating a bypass mechanism. This mechanism allowed solar energy transfer to the local power grid (WAPDA), while the load operated solely on the engine, achieving optimal energy sinking. The spinning unit had a 3MW roof-based installation, requiring low tension (LT) patching for seamless integration into the existing electrical infrastructure. Furthermore, a 1MW rooftop-based system was installed in the warehouse, with the solar source stepped up and patched into the main high tension (HT) system.

The installation process faced several challenges that required innovative solutions. Our effective management strategies and coordination were implemented to overcome these hurdles and ensure timely completion of the installation.

This successful installation of a 7MW solar power plant at Masood Spinning Mills by DSG Energy showcases the commitment towards sustainability and environmental responsibility. DSG Energy’s installation not only demonstrates the feasibility of large-scale solar projects but also showcases the potential for the textile industry to transition to clean energy alternatives. By embracing solar power, Masood Spinning Mills sets an example for other industry players to follow, promoting sustainability, reducing carbon footprint, and preserving the environment for future generations.

Overall, the collaboration between DSG Energy and Masood Spinning Mills exemplifies the potential of solar energy in revolutionizing the textile industry, offering a sustainable and environmentally responsible path towards a cleaner and greener future.