How Industrial Solar Systems Reduce Peak-Hour Costs for Factories

Industries across Pakistan often face a big challenge: high electricity charges during peak hours. Typically occurring from late afternoon to evening, these hours come with the highest rates because demand on the national grid spikes while supply falls short. For manufacturers, this means electricity bills soar, directly cutting into their profits.

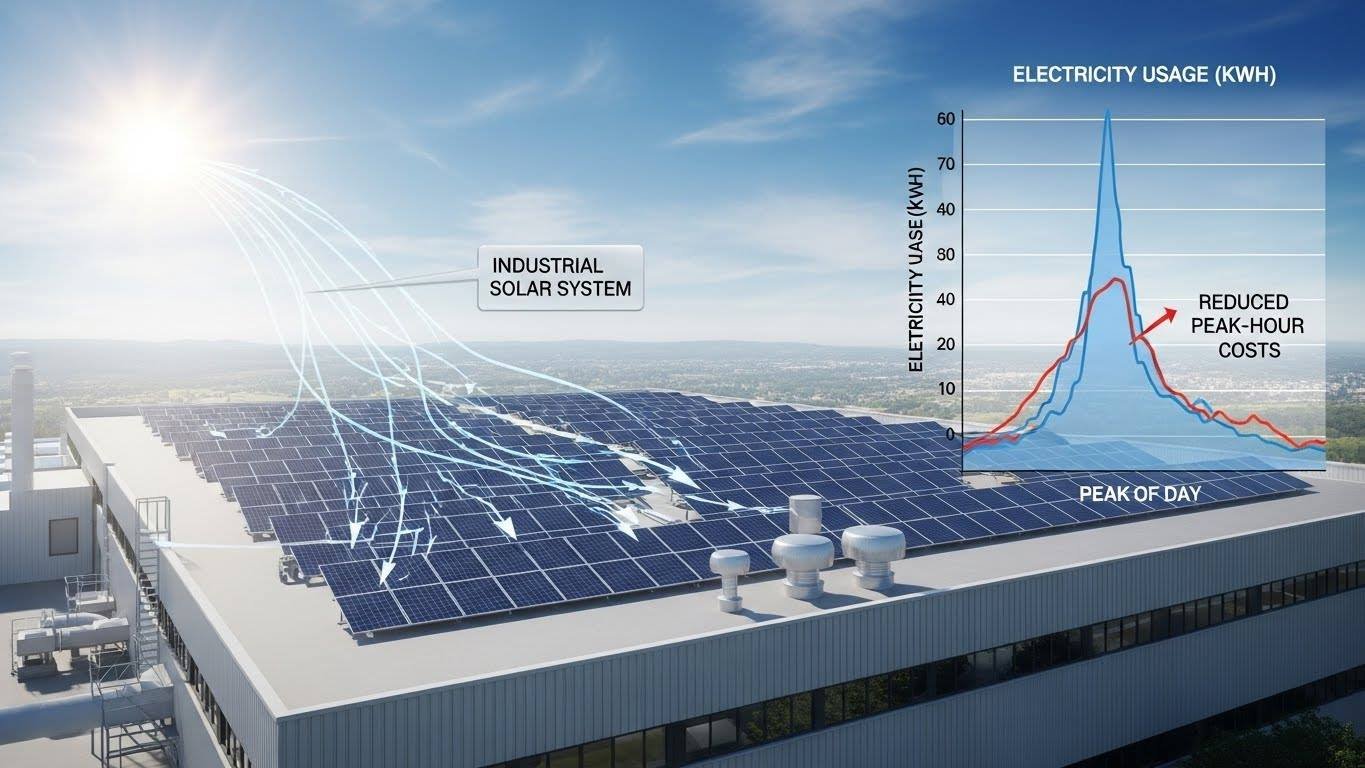

In recent years, industrial solar systems have emerged as one of the most practical tools to counter these costs. Factories are now turning toward large-scale solar installations not just for sustainability, but because the financial benefits are impossible to ignore. Here’s how industrial solar systems help reduce peak-hour costs and create long-term stability for industries in Pakistan.

1. Solar Power Offsets the Most Expensive Units of the Day

Peak hours are when electricity becomes the most expensive. Many factories simply reduce operations during this window to avoid the financial hit. However, solar changes this pattern entirely.

Industrial solar systems generate their highest output between 10 AM to 4 PM, which overlaps significantly with the period leading into peak hours. This means factories start entering the peak window with solar already covering a major chunk of their load. By the time peak kicks in, the grid import is already minimized.

The result is simple:

- Lower kWh consumption during expensive hours

- Reduced peak demand surcharge

- Lower overall monthly electricity bill

For industries relying heavily on motors, compressors, and production lines, even a small reduction in peak load translates into sizable savings.

2. Solar Cuts Down the “Peak Demand Charges”

Factories in Pakistan are billed not only for consumption but also for demand. The highest amount of power drawn at any moment during a billing cycle determines the demand charge.

Industrial solar reduces the dependence on the grid during daytime, lowering the maximum load recorded. When peak demand goes down, the recurring monthly demand charge also drops—helping factories save even if their production levels increase.

Many industries report that their demand peak drops significantly within the first few months of going solar, which directly brings down their fixed electricity costs.

3. Solar Supports Machines During Load Fluctuations

During peak hours, the grid comes under pressure, causing voltage drops and fluctuations. This makes motors, chillers, blowers, and other equipment run inefficiently, which ends up increasing electricity consumption.

A stable solar system:

- Smoothens the load

- Reduces dependency on inconsistent grid voltage

- Improves equipment efficiency

- Prevents the sudden spikes in consumption that raise bills

The solar system acts like a buffer, helping factories avoid the hidden costs of running machinery on weak grid supply.

4. Solar Enables Peak-Shaving With Zero Fuel Cost

Factories traditionally use generators to deal with peak hours. But diesel and gas prices are unpredictable and constantly rising. Running generators during peak hours can sometimes cost more than the grid itself.

Solar provides a cleaner and more affordable solution.

Through peak shaving, solar reduces the amount of grid or generator power needed at the most expensive period of the day. The best part? There is no fuel cost.

For large facilities like textile mills, pharma plants, and packaging units, this reduction in generator reliance can save millions annually.

5. Solar Integrates Easily With Existing Factory Systems

Industrial solar doesn’t require major structural change. It can be synchronized easily with:

- Grid power

- Existing backup generators

- Manufacturing equipment

- Plant automation systems

For factories operating in two or three shifts, this flexible integration is crucial. The goal is not just saving money but maintaining uninterrupted operations.

6. Net Metering Further Offsets Peak-Hour Electricity Load

Many industrial customers in Pakistan use net metering, allowing them to send excess solar energy back to the grid and earn units in return. Although net metering doesn’t directly eliminate peak charges, it helps in two ways:

- Overall bill reduction

Units exported earlier in the day help offset the more expensive units consumed later. - Load balancing

Factories that close before evening hours can export all afternoon and use these credits to cover consumption in peak hours.

In other words, solar doesn’t just reduce the power you buy during peak time—it boosts the total number of units you save across the entire billing cycle.

7. Long-Term Protection Against Tariff Hikes

Industrial tariffs in Pakistan fluctuate frequently. Every few months, fuel adjustments and policy changes lead to sudden jumps in electricity bills—especially during peak hours.

Solar gives factories a long-term hedge against these unpredictable increases. Once installed, the cost of solar energy remains almost fixed for the next 20–25 years. This stability is especially valuable for industries that prepare annual budgets and financial forecasts.

Instead of reacting to tariff hikes, factories with solar become power producers during the day—keeping operating costs predictable.

8. Better Energy Planning and Load Management

When factories generate their own energy, they gain better control over how and when different machines operate. Solar helps industries:

- Spread out heavy loads earlier in the day

- Reduce unnecessary operation during peak hours

- Maintain productivity without paying premium rates

This results in smarter energy usage across the entire facility. Many factories report that once solar is installed, energy wastage naturally decreases because production managers can plan around solar availability.

A Future-Focused Energy Advantage

Industrial solar is no longer just an environmental choice—it has become an essential financial strategy for Pakistan’s manufacturing sector. By cutting down peak-hour electricity costs, reducing reliance on unstable grid supply, and offering decades of cost stability, solar empowers industries to operate more competitively in local and global markets.

Powering Industry With Smarter Energy

As electricity demand keeps increasing in Pakistan, peak-hour prices will rise ,but solar offers a smart and steady solution. Factories that take the step now end up cutting costs and keeping their operations steady in the years ahead.

Companies like DSG Energy are already helping industries move toward smarter, cleaner, and more cost-friendly power solutions. Their reliable industrial solar systems make it easier for factories to handle peak-hour pressures while gaining real financial benefits.

FAQs

Not entirely. But they significantly reduce the units drawn during peak hours, bringing down both consumption charges and peak demand surcharges.

Yes. Even if production continues at night, daytime solar generation offsets a large portion of the total daily load, reducing overall bills.

Yes. With proper system design and synchronization, solar can comfortably support heavy industrial loads during the day.